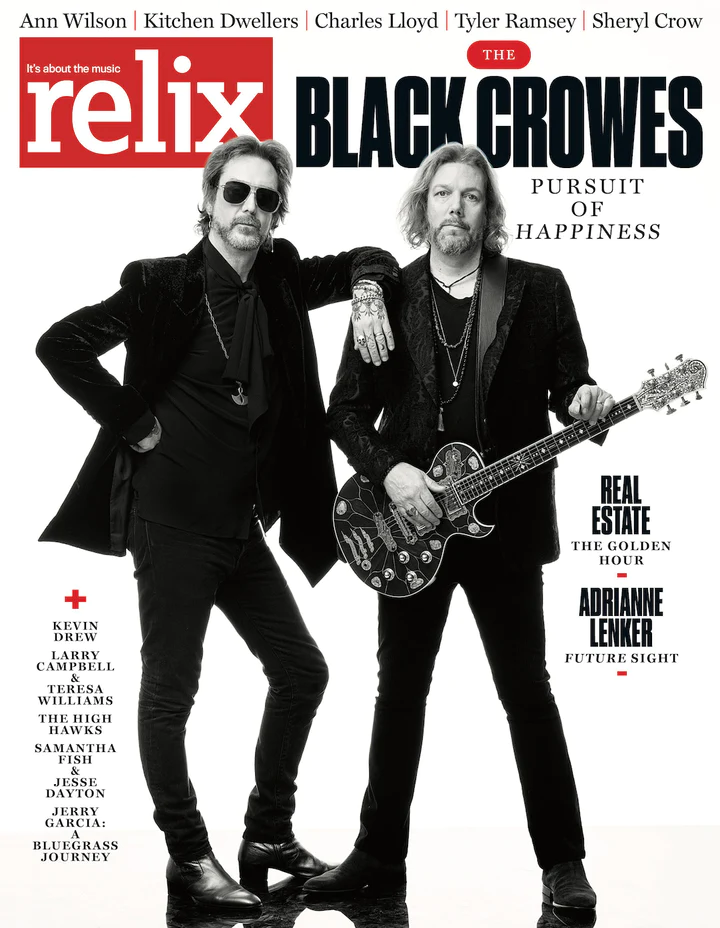

Pilot Season: The _Relix_ Collaboration with Sweetwater and Kyle Hollingsworth (Part Two)

Kyle Hollingsworth and Dean Budnick adding hops to the brew kettle

***

This is part two of the beer collaboration story with Kyle Hollingsworth and SweetWater. You can read part one here and part three here.

***

In our October/November issue, I shared an account of my early days as a homebrewer and described how Relix has come to partner with String Cheese Incident keyboardist Kyle Hollingsworth and SweetWater Brewery on a collaborative beer. I also tracked the initial stages of the process as we made our way to Crosby Hop Farm in Woodburn, Ore. to select the hops that we would use. Our story now continues in early November, as Kyle and I make our way to SweetWater’s Atlanta home base to brew the pilot batch.

You can now head over to the Relix Facebook page to help name the beer and win 2 tickets to the February launch event + lodging in Brooklyn!

***

Kyle pours a 420

While all those enzymes were reacting with the starches (brewing is both art and science after all), we had time to make the rounds inside the facility. We saw the various tanks (including our beer’s future home, the Dank Tank), leading up to the massive 400-barrel tanks—there are 31 gallons to a barrel—which are operated through a multiscreen computer interface. Then, we watched the bottling operation and the process by which kegs are refilled (after they are steamed and cleaned “to get off the guacamole,” Nick suggested). Kyle even pulled a beer off the bottling line for his own Laverne & Shirley moment. (Watch the opening theme on YouTube if this reference eludes you—I brook no opinion as to whether Kyle is Laverne or Shirley.) We were also on hand for the daily sampling process in the SweetWater lab, where they taste everything that’s heading out (and a few brews still in process) to ensure that the beer is consistent and worthy of being shared with the world (a.k.a. “true to brand”). Finally, Nick Burgoyne joined us over at the Woodlands where we sampled some barrel-aged beers. All told, if you have a chance to tour SweetWater, I heartily recommend it.

Kyle samples in the Woodlands after Nick Burgoyne removes a nail

* * *

“My early homebrew days were due to my brother,” he says. “Anything he did was super cool—he listened to the Grateful Dead first and then I listened to the Dead—and he was into homebrewing, which I thought was cool. I really enjoyed two parts of it. I enjoyed the process of creating something out of four ingredients—putting something together and having something completely different come out the other end. And it was also fun to have brother time and create something together. So that was an early part of it—the passion of brewing and also the passion of community and companionship. That community and companionship is also something I associate with beer in general.”

Nick Nock gets grabby on the bottling line

SweetWater’s Nick Nock’s echoed Kyle’s sentiments as he looked back on his early days at the brewery, which began over 20 years ago, when he became employee number one.

SweetWater variety packs offer bonus art action

As for the process of creating our beer itself, which continued through multiple hop additions after our sweet wort reached boil in the brew kettle—some of which you can see for yourself through the accompanying images, and look for more at relix.com, sweetwaterbrew.com and kylehollingsworth.com, as well as our social sites—I asked Nick to describe it in layperson’s terms:

“By the time you and Kyle had arrived, I pre-milled the malt we had agreed on, so it would be ready for us to get the mash going. Then we put in some base water and we added the malt as the rakes were stirring to make the mash, which has an oatmeal consistency. We agreed on the 149-degree mash set temperature, which is good because that would give us a lot of fermantables, but also leave some behind for a nice mouth feel. From there, we transferred to the kettle, sparging a little bit, which means adding more water to the mash and showering the grain to pick up any residual sugars.

“We did a five-barrel batch and we boiled it for an hour to sanitize the wort; during that process, we added the hops. We added a handful of hops up front, which is going to give us some bitterness. Then we went crazy on the back end, which is going to give us flavor and aroma, which I know we’re going to enjoy. Then we pitched the fermenter [adding yeast].

“Once it came out of the kettle, we had to cool it down because if you add boiling wort, it’s going to kill the yeast—the yeast is a living organism. So we went through a heat exchanger, and we knocked out into the fermenter at about 68 degrees. That’s where the yeast likes to thrive and, hopefully, by 6 a.m. tomorrow, we’re going to see some activity of fermentation—bubbles coming out of the blow off bucket, which would be a great sign.

“The next step is: We’re going to take samples of it daily to see what the gravity is, see how the yeast is reacting with the sugar water that we created. Then, at a certain time, we’re going to dry hop a lot, to add to the aroma of the beer—that should happen on day number three, day number four. Then, around day number seven, with the samples that we’ve been taking, we’re going to notice that the yeast has done its job; it’s not going to eat any more sugars. Once that’s the case, we’re going to chill it down from 66–68 degrees to 32–33 degrees—that’s going to make the yeast become dormant and drop out. From there, we’ll move it to another tank to let it condition for about a week, and then we’re going to move it to the brite tank, where we’re going to carbonate it. Then once it’s carbonated, it’s on…”

Kyle in the SweetWater lab

Click here for Part Three, in which we introduce Ground Score IPA.